Hydrated Lime Steel Silo Introduction

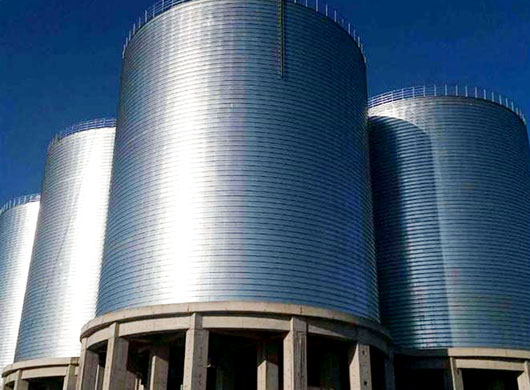

Lime silo system is a common method for the lime storage and transportation industry. SRON has two common silos types: Welded Steel Silo and Spiral Silo to store hydrated lime. Hydrated lime silo system includes steel silos and supporting auxiliary equipment, built for the storage and transportation of hydrated lime, and is widely used in building industry, petroleum industry, etc. SRON selects the most suitable and economical silo for clients according to their needs. At the same time, our sales staff and technical engineers can provide timely replies, professional silo knowledge and customized services according to clients' needs such as structure, silo design, silo capacity, and silo type.

If the client has a small demand for single silo storage capacity, then choose spiral steel silo(100ton-7000ton). The capacity of single welded steel silo can reach 100,000 tons, which is suitable for bulk storage.

Advantages of SRON Hydrated Lime Storage Silo

Good Overall Performance and Long Service Life.

During the construction process of lime steel silo, it is completely constructed by special equipment. The material of silo body can be selected according to the requirements of the anti-corrosion and grinding strength of the stored material, and the optimal plate ratio can be selected, so that its normal service life can reach 30-40 years, much longer than the service life of other silos.

Good Airtight Performance and Wide Use.

Adopts patent technology of vacuum sealing, the physical indexes of lime quality are basically unchanged within several months of storage inside silo. In the manufacture of steel silo we can ensure the quality of any part of the silo body in terms of technology, so its sealing is particularly good, and it can store lime, cement, fly ash, slag powder and other powders. It is widely used in building materials industry, such as cement plants, power plants, and grinding stations.

Short Construction Period and Low Cost.

Due to the adoption of various patented technologies, it can save about 50% of building material and more than 60% of land to be acquired. Help the clients to put into use and recoup funds quickly.

Small Floor Area and Easy to Manage.

The height and diameter of lime steel silo can be arbitrarily selected within a large range. The distance between the two silos is as small as 500 mm, which can make full use of the space and reduce the floor space. Lime steel silo has a high degree of automation, and is equipped with material level monitoring and other equipment, which is very convenient for users to manage.

High Strength and Light Weight.

The self-weight of SRON lime steel silo is only 1/6 of that of the concrete silo of the same volume. Its weight is the same as the weight of the steel bar of the concrete silo of the same volume, which can greatly reduce the load of the basic structure and the cost of building the silo.

Precautions When Storing Hydrated Lime

During the storage and transportation of lime, attention should be paid to fire prevention and explosion protection. Because quicklime will mature rapidly under the action of water and release a lot of heat, care should be taken to prevent burnout or fire.

Pay attention to respiratory protection when working, wear dust-proof fiber overalls, gloves, closed dust-proof glasses, and apply lubricating grease containing grease to prevent dust from entering.

Why Choose SRON Hydrated Lime Silo?

If you choose China's steel silo to store lime, SRON is the ideal choice. As one of the largest steel silo manufacturers in China, SRON has an annual production capacity of 30,000 tons. SRON own 80+ patented technologies. 9 invention patents among them. Moreover, we have an excellent team with more than 20 years of experience in silo construction, and have rich experience in the design, manufacture and construction of steel silo project and bulk material storage and transportation system project. SRON can provide the whole process turnkey project from consultation, design, production, on-site construction to silo system commissioning. So if you need to store lime or other materials, please contact us and we will be happy to design customized solutions for you.

Price of SRON Lime Silo System

If you are interested in our lime silo or want to know more details about the whole lime silo storage system, after understanding your specific needs, we have specialized technicians and salesmen who can provide you with the most economical and reasonable quotation and advice according to your needs.