Discharging Patterns of Steel Silo

Sep 21, 2017Keywords: steel silo, discharge pattern, steel silo discharge patterns

Steel silo has been widely used in storage, transportation and other fields owing to the characteristics of high land use rate, high degree of automation, short construction period, low investment costs. As economy develops, the obvious trend in the usage of steel silo is that the capacity of a single silo is becomes bigger and bigger . With the gradually increasing of silo capacity, how to ensure the smooth material discharging has become the key problem need to consider in the design of steel silo. Several common discharge patterns are as follows:

1.Full cone material self flow discharge

It includes concrete foundation (concrete cone) and whole steel braced. The advantages of this kind of discharge pattern: smooth material discharge, no residual in silo; adopt the automatically material flow discharging, process is simple and don’t need accessory equipment, easy to use; The storage capacity can be fully utilized without capacity loss, the full cone itself effectively add up the silo capacity; the construction period is short.

The shortcomings:The height of cone is high, result in higher silo foundation, so the civil engineering cost much. If the diameter of the silo is too large, the cost of civil construction will even exceed the cost of silo itself. So this discharge method is not suitable for the silo with too large diameter.

2. Half cone combine with backfill

Advantages: There is no residue basically in the silo; Adopt the material flow automatically discharging, no accessory equipment; The silo foundation can be built lower than the full cone.

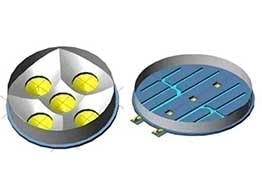

3. Flat bottom multi-point discharge

Open a certain number of discharge hole on the silo baseplate according to a fixed distance (usually odd number) . The advantages of multi points discharging of flat bottom silo: There is no backfill in silo, all the silo capacity can be used.

The shortcomings: the material in silo can't be unloaded to empty by gravity, Additional means need to be used to facilitate clearance.

4. multi-point discharge combine with backfill

The advantage is that there is no residue in silo, adopt the automatically material flow discharge, no need of accessory equipment; The backfill quantity is small, silo capacity loss less.

Shortcomings: still have some loss in silo capacity, the backfill process is complex so the construction is difficult.

5. Fluidized discharge

On the backfill slope (the angle is small), make special shape air duct, and arrange a sieve plate on the air duct, by the action of the airflow, residual material forme a semi suspension state on the air channel. The advantages of Fluidized discharge is: discharge with the assistant of fan, less residue in silo; less backfill quantity, less silo capacity loss. Besides, due to large number of air ducts and uniformity laying, the ventilation effect is good.

Shortcomings: the backfill process is complex, difficult construction; still have some loss in silo capacity; Fluidized discharge is not stable.

Summary:

The effect of discharging (less residue): Full cone= Half cone backfill> Multi-points backfill>Flat bottom silo

The capacity utilization rate: Full cone=Flat bottom silo> Multi-points backfill > Half cone backfill

Civil engineering cost: Full cone> Half cone backfill> Multi-points backfill> Flat bottom silo

Contact US Now!