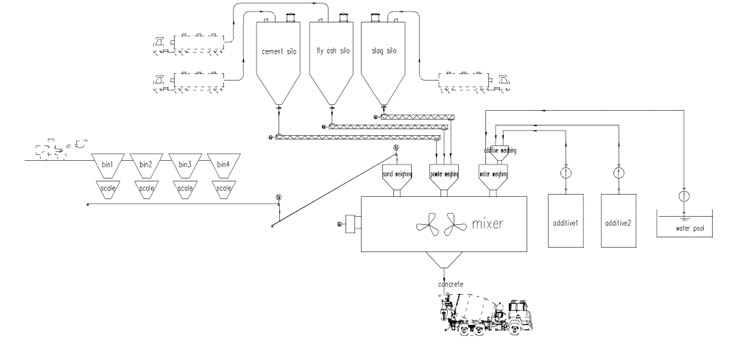

SRON Steel Silo System in Concrete Batching Plant

Batching Plant Silo Solution: A Practical Guide to Selection, Safety & Compliance

Types & Capacities

For concrete plants, bolted, welded silos are common; you’ll also choose between vertical and horizontal/mobile designs. Typical capacity bands: 50–100 tons (small/temporary plants), 200–500 tons (most ready-mix sites), and 1000+ tons for industrial-scale supply.

Quality steel materials and standardized fabrication extend service life and reduce maintenance.

Feeding & Discharge

Mechanical feeding (belts, bucket elevators, screw conveyors) offers low energy consumption for short distances, while pneumatic feeding (from bulk tankers to closed pipelines) enables dust-tight, long-distance transfer. A hybrid scheme often works best.

On discharge, gas-fluidized floors + pipeline transfer secure high emptying rates and continuous supply; a single line can reach up to 500 T/H, with dual/multi-line combinations for higher throughput.

Safety & Environmental Control

A top-mounted dust collector is essential to control emissions and meet regulations. Ensure correct filter media, air-to-cloth ratio and differential pressure limits.

During filling, activate filters, open pinch valves and monitor pressure. Implement overpressure protection (safety valves/rupture discs, alarms, interlocks) to prevent structural damage.

For fly ash silos, strengthen moisture protection, explosion venting and inspections, with sensors for temperature, combustible gases/dust and level.

Smart Operations

Plants often run 5–8 silos (cement, fly ash, SCMs). Tie silo level/temperature/humidity into a connected platform for inventory visibility, coordinated dispatch, and early warnings. Selection

EPC Delivery

Match capacity to peak hourly demand and tanker turnaround; align cone angle, aeration and flow aids with powder properties; confirm foundations and mobility needs; specify dust airflows and overpressure devices; add sensors/telemetry; and set emptying performance targets (e.g., >95% residual-free). Choose EPC providers with proven multi-silo clusters, enclosed galleries and dust platforms.