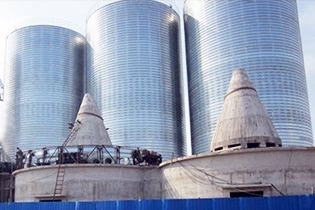

Cement powder has good fluidity, its storage requires high strictness of sealing, silo solidity and scientific arrangement of aeration system ensuring smooth and high rate cement unloading.

Each project is customized designed as per different functional needs, site geographic situations and investment plan.

Introduction

Details

Silo Feeding System

Silo Feeding System Pneumatic Feeding

Pneumatic Feeding Silo Aeration System

Silo Aeration System Silo Aeration System

Silo Aeration System Silo Discharging System

Silo Discharging System Bulk Truck Loading System

Bulk Truck Loading System Dust Collector System

Dust Collector System Bag Packing System

Bag Packing SystemExhibiton Information

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.