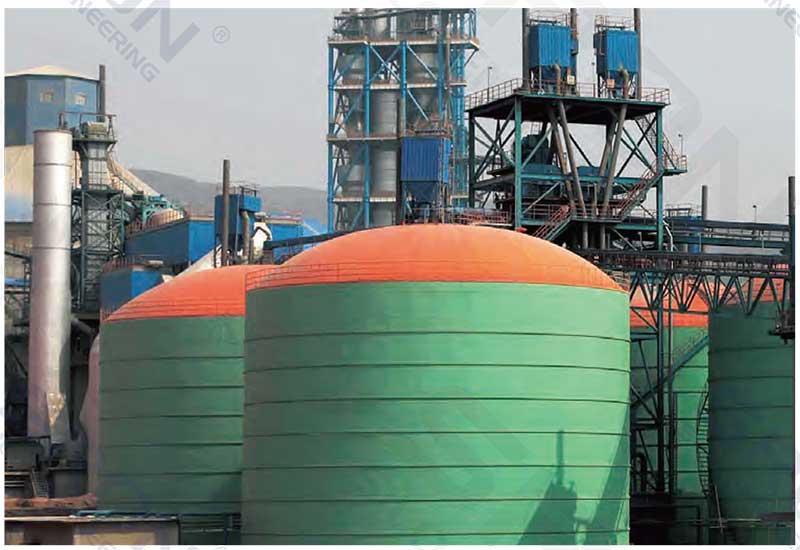

Large welded steel silo, which is mainly made of welded steel plate, is a self-developed independent silo type in the continuous development of China's steel silo industry. The effective diameter of the welding steel silo can reach tens of meters, the silo body is cylindrical, the top of the silo is spherical, and the wall of the silo is in the form of steel frame.

Our company has obtained more than 20 patents in silo shape and internal structure, and has scientific and advanced silo design concept

Introduction

Welded silo is full welded at site by licensed expertise welders and by strict project site management system.

Details

Structural Safety

As a high-load thin-walled structure building, the safety of the steel silo has a high priority. SRON engineer fully consider various factors, like dead loads, dynamic loads, grain loads, earthquakes, wind loads, snow loads, temperature effects, etc. in the early design stage of silo system.

For overseas projects, we fully consider the differences of national standards, uses international standards and professional industry software such as STAD PRO and SAAP2000, and uses finite element analysis to produce effective structural calculations.

.jpg)

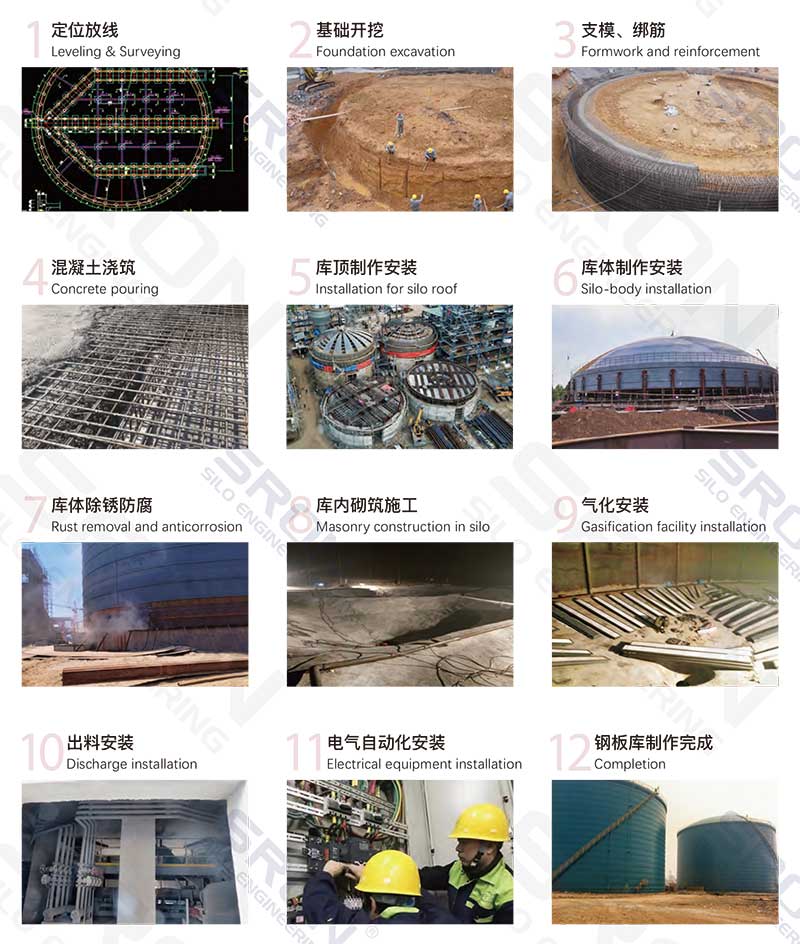

Construction Process of Welded Steel Silo

3D Show of the installation process of welded steel silo

Exhibiton Information

Please feel free to give your inquiry in the form below. We will reply you in 24 hours.