The Ultimate Steel Silo Selection Guide(2026)

Dec 31, 2025Keywords: Steel Silo Selection Guide,Steel Silo Buying Guide,SRON Silo

When choosing a steel silo, are you overwhelmed by so many options—corrugated bolted silos, spiral folded steel silos (Lipp silos), bolted steel silos, and welded steel silos? Should you choose a flat-bottom silo or a hopper-bottom silo? If you plan to store 6,000 tons of material, is it better to build one large silo or several smaller silos? If the material is moisture-sensitive and requires high airtightness, which structure is best? If the project schedule is tight, which silo can be built the fastest? If the budget is limited, which option offers the best value? If you focus on long-term service life, safety, and durability, which structure should you prioritize? And with steel silo suppliers varying widely in quality, how do you choose a reliable manufacturer?

Do you have the same questions during the steel silo purchasing process?

This Steel Silo Buying Guide will answer all of the above questions at once and help you make the best decision.

Steel silos can first be divided into two major categories based on stored material: grain steel silos and industrial steel silos. They differ in design priorities and selection criteria.

Stored materials: all kinds of grains and agricultural products, such as wheat, corn, soybeans, rice; also feed pellets, oil crops, flour, dried fruits, etc.

Typical applications: farms, grain processing plants, edible oil factories, feed mills, poultry farms, national grain depots, transit storage and reserve depots, etc.

Common silo types: corrugated bolted steel silos, aluminum silos / stainless steel silos (304/316)

Grain storage is dominated by corrugated bolted steel silos, with a market share of over 90%. This type is technically mature, fast to install, widely applicable, and cost-effective—making it the preferred structure for global grain handling and storage projects. Only when the stored product has special material restrictions (for example, dried fruits, nuts, flour, etc. with strict limitations on galvanized coatings) are aluminum or stainless steel silos considered.

Stored materials: cement, clinker, fly ash, limestone, calcium carbonate, alumina, steel slag powder, coal, plastic pellets, wood pellets, and many other industrial bulk materials.

Industries / scenarios: cement & building materials, fly ash silos in thermal power plants, bulk yards, coal mines and mineral mines, aggregate storage, grinding stations, truck loading stations, bulk terminals/ports, chemical plants, biomass power plants, etc.

Common silo types: mainly bolted steel silos, spiral folded steel silos (Lipp silos), and welded steel silos.

Compared with grain silos, industrial silos focus more on structural strength and diversified discharge methods, and the final selection is usually based on material characteristics and capacity scale.

By structural form and construction method, steel silos can be categorized into the following types:

Single-silo capacity: 15–15,000 tons (based on wheat density 0.75 t/m³)

Diameter: approx. 1.8–30 m

Suitable materials: mainly grains and other granular materials. Not suitable for large-scale storage of powder materials (because powders have poor flowability and are prone to dusting), but can be used for fine granular materials with low stickiness such as soybean meal (in this case, single-silo capacity should not be too large).

Structural features: silo wall assembled from galvanized corrugated steel sheets, relatively thin wall plates (1.0–8.0 mm) connected by high-strength bolts. External vertical stiffeners and circumferential wind rings are installed to enhance strength. The roof is usually a conical roof with roof ladder, manholes, etc.

Advantages: light self-weight, highly standardized components, simple and fast site assembly. Fully galvanized structure offers good corrosion resistance. Grain conditioning systems (aeration, temperature monitoring, etc.) are well-developed. Among all types, corrugated silos usually have the lowest cost per ton of storage, with mature product systems—making them the first choice for grain transit and turnover storage.

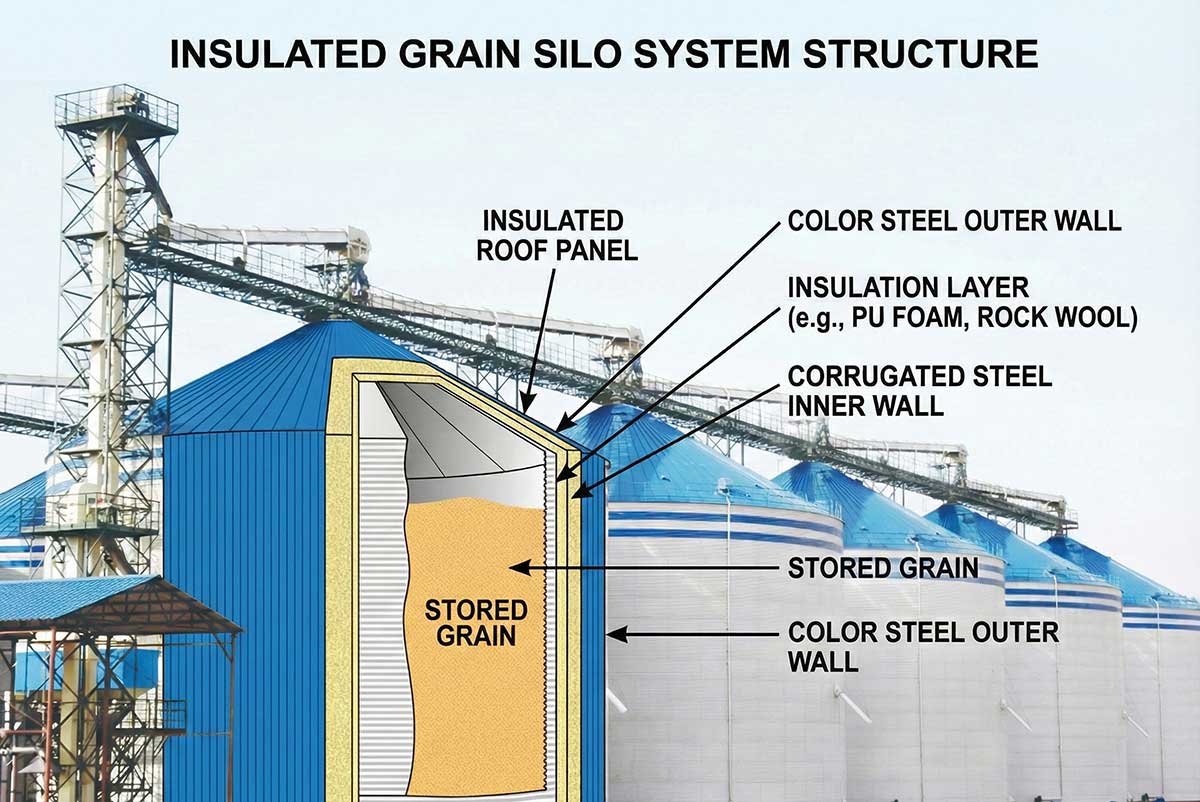

Limitations: airtightness and thermal insulation performance of standard corrugated silos is relatively weak, making them less suitable for long-term storage or materials requiring strict storage conditions. If insulation is needed, an insulated steel silo can be used (corrugated bolted silo + insulation layer + protective cladding).

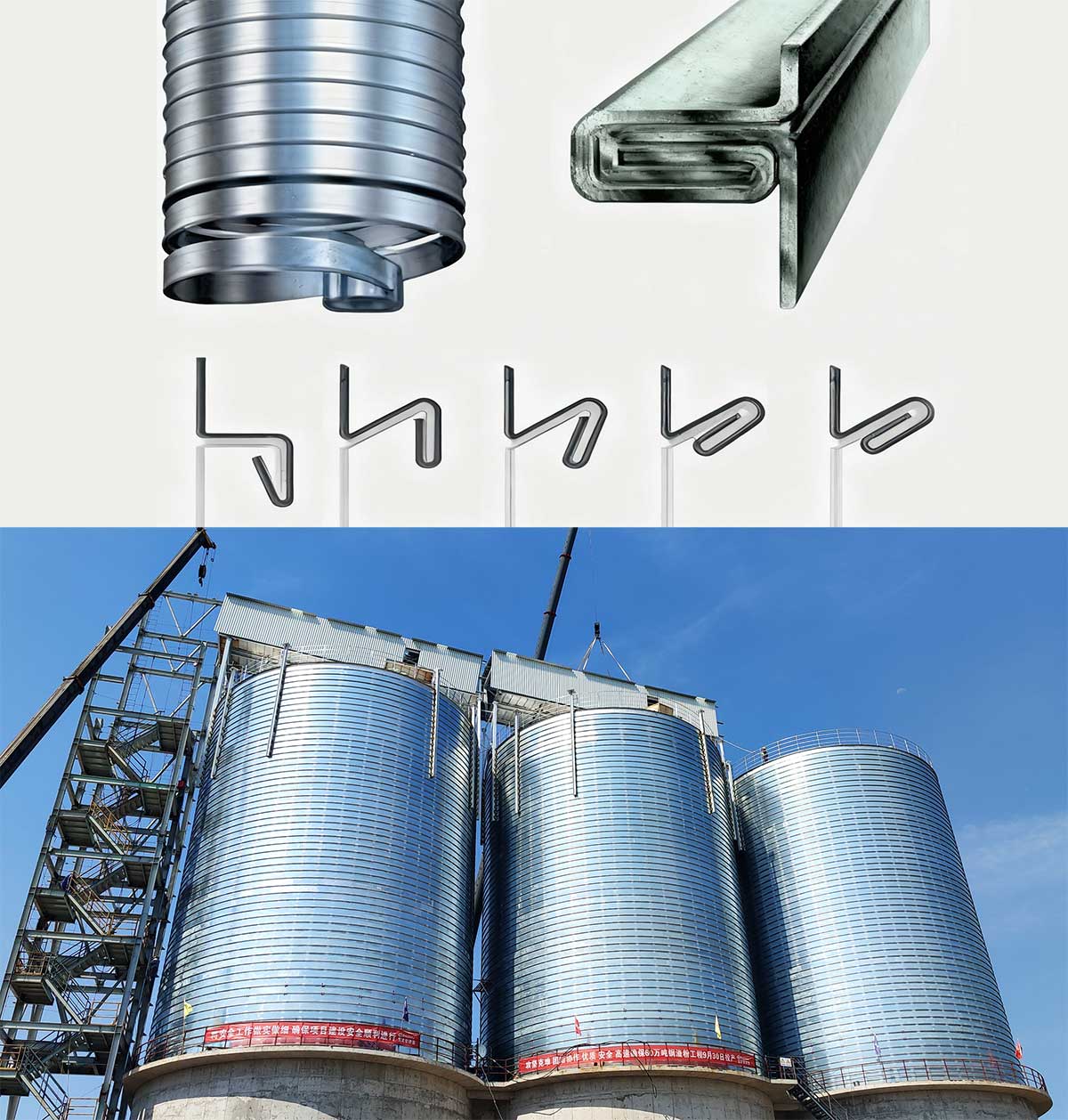

Manufacturing process

Galvanized sheets are processed in the factory through corrugating, punching, bending, and cutting to form corrugated panels.

Image: manufacturing photos

Installation process

On-site installation is done by bolting. Typically, the roof is assembled first, then wall sheets and stiffeners are assembled ring by ring from top to bottom. Construction time is short—large grain silos can often be installed within a few weeks.

(mainly for ≤7,000 tons when fast construction or high airtightness is required)

Single-silo capacity: about 100–7,000 tons (based on wheat)

Diameter: approx. 6–25 m

Suitable materials: both grain and industrial materials. For grain storage, it is recommended to use an external-column design to reduce grain residue and wall buildup. For grain storage, the total cost is generally higher than corrugated bolted grain silos.

Structural features: the silo wall is formed by on-site roll forming and seaming of flat steel plates into a five-layer overlapped spiral seam (spiral ring reinforcement), combined with internal/external vertical stiffening columns. Wall thickness typically 2.0–5.0 mm.

Advantages: formed on-site using special equipment; can operate continuously 24 hours. A 5,000-ton class silo can often complete the shell construction within a few days. Fast construction, light weight, good airtightness—the five-layer seam provides reliable sealing performance.

Limitations: requires dedicated roll-forming equipment and an experienced installation team. For smaller projects, equipment mobilization and travel costs are high, increasing unit cost. The connections between shell and columns require on-site welding; galvanized coating may be locally damaged, so secondary anti-corrosion treatment is required at welded areas to ensure service life.

Manufacturing process: only the roof, columns, and steel structures need to be prefabricated; the silo shell is formed directly on-site.

Installation process: the folding machine continuously forms the wall; each coil edge is locked into a five-layer seam while vertical columns are intermittently welded as support. Overall construction is faster than most other types.

(typically for industrial materials ≤2,000 tons per silo; easy installation, convenient transportation, detachable and reusable)

Capacity: 50–2,000 tons (based on cement)

Diameter: approx. 2.9–21 m

Suitable materials: industrial materials such as cement, sand, gypsum powder, etc.

Structural form: flat plates with folded flanges; horizontal and vertical flanges act as circumferential and vertical stiffeners after assembly.

Wall thickness: about 4–10 mm

Advantages: usually smaller in size; all components can be precisely prefabricated in the factory, ensuring high installation accuracy and a simple on-site process. For small silos, the shell can be assembled on the ground and lifted into place as a whole, significantly shortening the schedule. Easy to dismantle, relocate, and reuse—ideal for temporary storage or projects requiring relocation with changing operating conditions.

Limitations: single-silo capacity is limited by plate and bolt strength, typically not exceeding 2,000 tons. Many flange joints exist; long-term service requires periodic checks for gasket condition and bolt loosening.

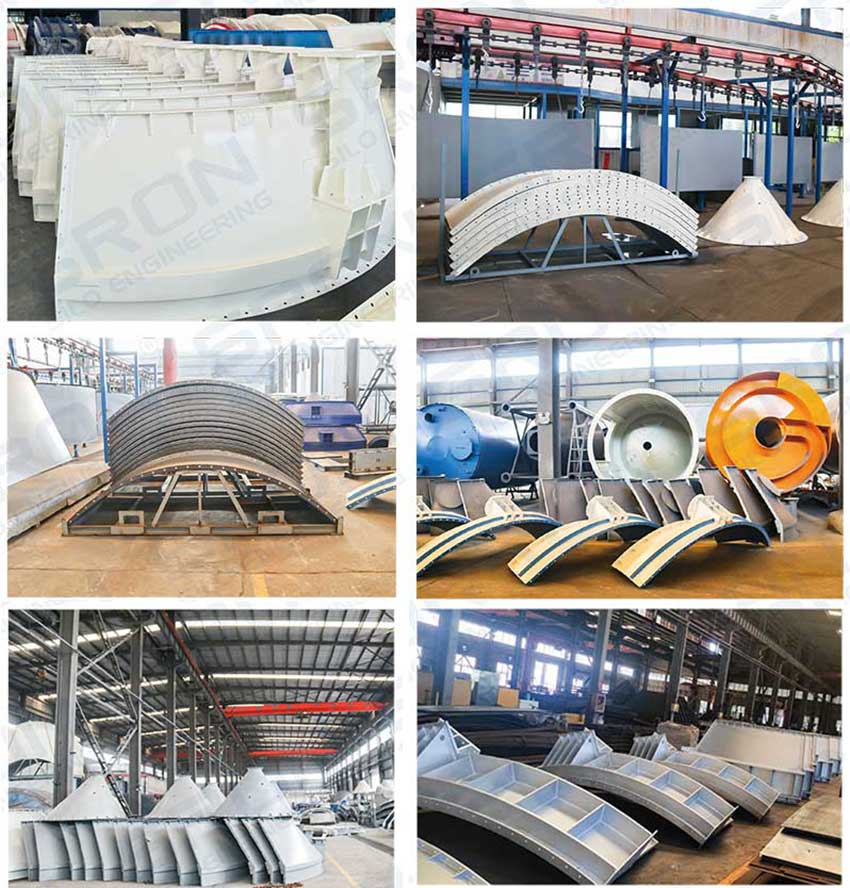

Manufacturing process: plates are cut to size, then press-formed on four sides; stiffeners and flange holes are punched in one process to ensure interchangeability. Some hopper-bottom or leg components are prefabricated and welded in the factory.

Installation process: if the site allows, the silo can be assembled on the ground and then lifted onto the foundation by crane; or assembled ring by ring from bottom to top. Low machinery requirements and low technical difficulty.

(typically for long-term or large-volume storage of cement, fly ash, etc., with single-silo capacity around 10,000 tons or above)

Capacity: 1,000–100,000 tons (based on cement density 1.3 t/m³)

Diameter: approx. 11–83 m

Suitable materials: both granular and powder materials; widely used. Large powder storage facilities in building materials, power, and metallurgy industries (e.g., cement clinker silos, fly ash silos) commonly use this type.

Structural form: shell formed by on-site welding of steel plates, with thicker wall plates (6–25 mm) and circumferential/vertical stiffening ribs. When roof diameter is large, a truss roof is often used. If belt conveyors/pipe galleries or heavy equipment loads must be supported, a space frame (spherical reticulated) roof can be adopted to increase load capacity.

Advantages: extremely large single-silo capacity; diameter and height can be customized for process layout. Fully welded structure provides the best airtightness—suitable for moisture-sensitive materials or strict sealing requirements. High structural strength, good wind/seismic resistance, long service life (often 30–50 years). In coastal/high-humidity regions, its corrosion resistance can be especially advantageous.

Limitations: heavy structure; large amount of on-site welding requiring high-level welding workmanship, longer construction period. Higher cost. Quality is heavily influenced by on-site management and welder skill.

Installation process

On-site welding workload is high and requires advanced welding and inspection; construction period is long. Cost is relatively highest, and quality depends strongly on on-site welding level.

| Silo Type | Single-Silo Capacity (t) | Suitable Materials & Scenarios | Structural Features | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Corrugated bolted silo | 15–15,000 (grain) | Grain & granular materials; depots, processing, transit storage | Thin corrugated galvanized plates + external stiffeners; bolted assembly | Mature and reliable; fast installation; complete systems; fully galvanized, low cost per ton | Weaker airtightness & insulation; not suitable for long-term storage of high-moisture materials |

| Spiral folded silo (Lipp) | 100–7,000 (grain) | Grain & industrial bulk; fast build or high sealing needs | On-site formed smooth wall; five-layer spiral seam + columns | Fastest build speed; good airtightness; smooth wall reduces material sticking; light weight | Requires special equipment & skilled crew; high mobilization cost for small projects; local anti-corrosion reinforcement needed |

| Bolted steel silo | 50–2,000 (cement) | Industrial powders; small-batch storage; temporary/movable storage | Flat plates with folded flanges; high-strength bolting | Simple installation; can be assembled on ground and lifted; easy to dismantle/relocate/reuse | Limited single-silo capacity; many flange bolts—requires periodic sealing/bolt checks |

| Welded steel silo | 1,000–100,000 (cement) | Powders & granules; large long-term storage facilities | Thick plates welded on-site; internal/external stiffeners | Largest capacity; high strength; good airtightness; long life (50+ years possible) | Highest cost and construction effort; long schedule; quality depends on on-site welding |

Single-silo capacity selection should consider material properties, storage purpose, site conditions, and infeed/outfeed methods. Bigger is not always better—reasonable compartmentalization often achieves a balance of safety, flexibility, and operating efficiency.

Most grains can be stored in corrugated bolted silos, with single-silo capacity ranging from a few hundred tons to over 10,000 tons. For typical grain turnover or reserves, 100–15,000-ton corrugated bolted silos can be selected. If insulation is needed, consider an insulated steel silo (corrugated bolted silo + insulation + protective layer). For materials with special material requirements (such as dried fruits, peanuts, flour, etc.), aluminum or stainless steel small silos are recommended, usually with single volume below 500 m³, to avoid potential contamination risk from galvanized coatings.

Grain storage (100–15,000 t): corrugated bolted silo

Dried fruits, peanuts, flour, etc. (single silo < 500 m³): aluminum or stainless steel silo

< 1,000 t per silo: bolted steel silo; small welded silo

1,000–2,000 t: bolted steel silo; small welded silo; or spiral folded silo

2,000–8,000 t: large welded silo or spiral folded silo

> 8,000 t: large welded silo

.jpg)

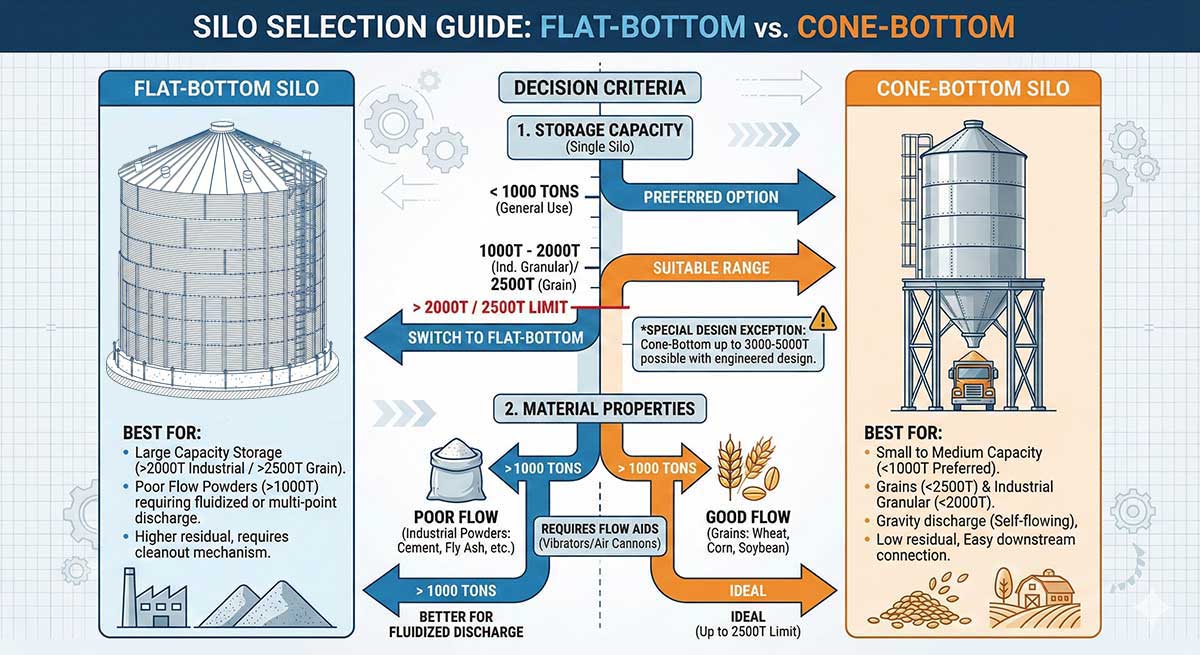

For any steel silo type, there are two basic bottom structures: flat-bottom and hopper-bottom. The correct bottom selection directly affects discharge efficiency, residual rate, and construction cost.

Generally, when single-silo capacity is below 1,000 tons, whether for grain or industrial materials, hopper-bottom silos are preferred unless there are special requirements. Hopper-bottom silos use gravity discharge, have minimal residue, and typically do not require a bin sweeper—resulting in lower operating and maintenance costs. The hopper outlet can connect easily to truck loading, batching scales, bulk bag packing machines, etc., with accurate metering.

Recommended hopper-bottom capacity limits:

Grain materials: typically ≤ 2,500 tons per silo

Industrial materials (usually granular): typically ≤ 2,000 tons per silo

Above these ranges, a flat-bottom design is generally recommended.

Note: with special cases and special designs, hopper-bottom silos can reach 3,000–5,000 tons, but this requires specific engineering design.

Industrial powders (cement / fly ash / gypsum powder / fine clinker): poor flowability, prone to arching/bridging. Below 1,000 tons, hopper-bottom may be used with vibration discharge or air cannons, etc. Above 1,000 tons, flat-bottom is preferred (fluidized bottom / multi-point discharge / air slides are easier to arrange).

Granular grains (wheat, corn, soybeans, etc.): good flowability; hopper-bottom can be used (typically for ≤2,500 tons per silo).

If frequent material changeover, batch discharging, or blending-buffer operation is required, hopper-bottom silos are better due to gravity discharge and low residue, enabling faster switching. For seasonal procurement or long-term reserve storage with concentrated large-volume in/out operations, flat-bottom silos offer broader capacity options and lower cost per ton.

Grain reserve depots / rice mills (hot & humid regions): use large-capacity flat-bottom main storage (3,000–8,000 t each), plus several hopper-bottom turnover silos (200–600 t each) for daily turnover and delivery. Flat-bottom silos can be equipped with above-ground aeration ducts, roof ventilators, temperature cables, and consider airtight sealing and recirculating fumigation systems for long-term safety.

Feed mills: build multiple small-to-medium hopper-bottom silos (100–500 t) for different recipes/materials to avoid cross-contamination and residue, plus a small number of flat-bottom silos as daily/weekly reserve to reduce cost per ton.

Regional distribution hubs / rail-road intermodal transit (railcar/ship to truck):

Cement: hopper-bottom silo (commonly 1,000–2,000 t)

Fly ash: hopper-bottom silo (commonly 500–2,000 t)

For larger capacities or lower cost per ton: flat-bottom + fluidization / air slides

Port / high-throughput “ship ↔ land” bulk transfer stations (buffer + short-term storage):

Cement: typically 3,000–10,000 t per silo (mainly flat-bottom with fluidized bottom)

Fly ash: typically 2,000–5,000 t (more emphasis on fluidization design and anti-arching)

Note: this is common for “transfer + buffering”; for more long-term reserve, a 10,000–30,000 t flat-bottom silo may be used—approaching terminal reserve rather than pure transit.

Cement plants and grinding stations: require large, long-term safe storage of finished cement or clinker; due to material properties and flow splitting requirements, they often need fluidization and multi-point discharge, so flat-bottom is used, typically with single-silo capacity ≥10,000 t.

If the main purpose is long-term reserve storage and capacity is about 1,000–3,000 t (grain) or 1,000–2,000 t (powders), prioritize flat-bottom silos for better economy and layout flexibility.

For turnover and dispatching scenarios requiring frequent cleanout and switching, prioritize hopper-bottom silos: gravity discharge, low residue, high efficiency, and good overall economy.

For powder silos requiring fluidization or multi-point discharge, flat-bottom is preferred (hopper-bottom is only suitable for small-capacity buffering and must be designed with large hopper angle + anti-arching/fluidization devices).

In practice, about 95% of projects can achieve the best performance/cost balance through a “flat-bottom main silo + hopper-bottom turnover silo” combination. Final方案 still needs professional design calculations and process layout to ensure both safety and cost-effectiveness.

When a project has specific requirements, silo selection should be adjusted accordingly:

If the material requires strict moisture/oxygen protection (e.g., food-grade grain storage, airtight fumigation pest control, or powder materials that absorb moisture and cake), select a structure with good airtightness and apply supporting sealing measures. Spiral folded silos (Lipp silos) have excellent airtightness due to their five-layer locked seam and are commonly used for airtight grain silos. For large industrial powder silos, welded silos or spiral folded silos are preferred.

To prevent large temperature swings or condensation (e.g., long-term grain reserves to reduce mold risk due to temperature differences), consider insulation design. Adding insulation outside a corrugated bolted silo (e.g., polyurethane foam, rock wool sandwich panels with outer cladding) is common. Good insulation stabilizes temperature/humidity and protects material quality.

Salt spray and high humidity accelerate corrosion. Use higher corrosion-resistance materials/coatings, such as thicker galvanizing or advanced Al-Zn-Mg alloy coated sheets, which can offer several times better corrosion resistance than traditional galvanizing. For welded silos in such environments, apply a full coating system after construction (zinc-rich primer + weather-resistant topcoat) to improve salt-spray resistance. Stainless steel silos provide best corrosion resistance but are expensive and used only in very special cases.

If rapid completion is required, select a type with short construction period. Spiral folded silos can be the fastest when the roll-forming equipment is available—medium silos can often be formed within days. Corrugated bolted silos use standardized parts and can be installed in parallel, also achieving short schedules. Welded silos usually take the longest due to welding and inspection. A practical approach is to stagger construction of multiple silos and use experienced installation teams to ensure schedule.

Under limited budget, choose the highest value option that still meets requirements. For large grain projects, corrugated bolted silos usually have the lowest cost per ton and low maintenance. For small-to-medium industrial projects, consider bolted silos or Lipp silos to reduce civil works and foundation investment. For small projects, avoid construction methods requiring expensive equipment to prevent unit cost inflation. Also consider operating costs—optimize life-cycle cost (LCC), not only initial CAPEX.

For long-term use with high safety requirements, increase design safety margins and consider maintenance convenience. Structurally, thicker-wall solutions (welded silos or reinforced bolted systems) can be preferred, with design life not less than 25 years. Configure safety monitoring systems (see below), and ensure construction and acceptance quality. Although long-life silos may require higher initial investment, lower maintenance and longer service life can reduce total life-cycle cost.

Steel silo design and fabrication must comply with relevant national/industry standards, such as:

China: GB 50322-2011 Code for Design of Grain Steel Silos (requires design life ≥ 25 years)

China: GB 50884-2013 Technical Code for Steel Silos

Europe: Eurocode EN 1991-4 (Actions on structures—Silos and tanks)

USA: ASAE EP433 (loads on grain bins)

Design verification per standards ensures sufficient wind and seismic resistance and meets safety factors.

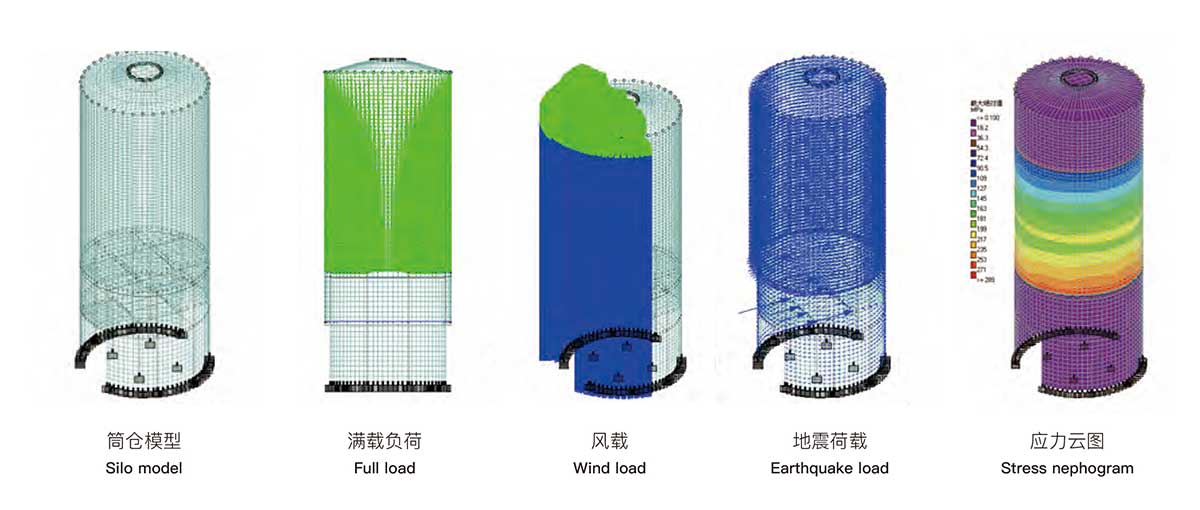

Silo loads are the “fundamental logic” of structural safety and service life. Design must consider not only static stored material weight, but also filling impact, eccentric discharge, local overpressure caused by flow blockage, plus external effects such as wind, snow, earthquakes, temperature changes, and uneven foundation settlement. Underestimating loads can lead to shell buckling, bolt fatigue, roof deformation, or even global instability. Unreasonable load assumptions can also create cracks and leakage points at ladders/platforms, dust collection and conveying interfaces, increasing maintenance cost. Following standards and performing load combinations based on material characteristics and operating conditions is key to long-term stable operation and reduced downtime risk.

Grain silos should be equipped with comprehensive aeration and grain-condition monitoring, including bottom aeration ducts and fans to release heat and balance temperature/humidity; temperature cables to monitor grain temperature and trigger aeration or grain cooling when needed; and recirculating fumigation systems for airtight silos to evenly distribute fumigant under sealed conditions. Industrial silos should include level gauges, high/low level alarms, internal pressure monitoring, and automated discharge control systems to prevent blockages and accidents.

Install dust collectors at roof vents, discharge points, and transfer interfaces to prevent dust leakage. This protects workplace environment and staff health and helps comply with local emission standards. For cement and fly ash silos in particular, consider roof dust filters, discharge point dust hoods, and negative-pressure dust collection systems for clean production.

Modern silo systems are increasingly intelligent. PLC/SCADA systems can provide centralized control and data acquisition, enabling remote monitoring and even unmanned operation—such as automatic aeration control, temperature/humidity adjustment, level monitoring alarms—improving efficiency and reducing human error. Advanced systems can upload data to the cloud for multi-site monitoring and data analysis to optimize inventory and dispatching.

verify the manufacturer’s compliance with international standards. A reliable supplier must hold ISO 9001 Quality Management System certification to ensure process consistency. For global projects, look for CE Certification (specifically EN 1090 for steel structures) and a willingness to undergo Third-Party Inspections (e.g., SGS, BV, TUV). These credentials are the strongest proof of a supplier's manufacturing capability and guarantee the structural safety of your silo.

Steel silo selection may seem complex, but you can find the optimal solution by following these principles:

Clarify material characteristics and required capacity;

Choose the appropriate silo type and bottom layout based on process flow and site conditions;

Balance investment cost and service life—focus on long-term returns, not just initial cost;

Work with a professional supplier for end-to-end design, manufacturing, and construction to ensure safety, reliability, and economic performance.

With the analysis in this guide, you should now have a comprehensive understanding of steel silo selection. If you want a customized solution based on your project parameters, Ready to build your storage project? Contact SRON's engineering team today for a free consultation and a customized silo design proposal.

Answer: It depends on the purpose and process.

Mainly long-term reserve: recommend 2–3 flat-bottom main silos to share risk; maintenance won’t stop turnover; lower cost per ton.

High-frequency turnover / multi-product switching: use a combination of flat-bottom main storage + several hopper-bottom turnover silos for fast truck loading and accurate metering.

Limited site / foundation bearing capacity: multiple silos may be easier to arrange and build in phases.

Answer:

< 1,000 t: prioritize hopper-bottom (gravity discharge, low residue, fast metering).

Grain 1,000–2,500 t / industrial granular 1,000–2,000 t: both possible—decide by operation mode and budget.

Above these capacities OR powders requiring multi-point/fluidized discharge: prioritize flat-bottom.

Most projects achieve best performance/cost with “flat-bottom main + hopper-bottom turnover”.

Answer:

Airtight grain storage / fumigation needed: spiral folded (Lipp) silo has clear airtightness advantages, or use an airtight-upgraded corrugated bolted silo (enhanced sealing).

Long-term airtight powder storage: welded silos provide the best airtightness due to continuous weld seams.

Supporting measures: double sealing doors, flange gaskets, roof dehumidification and gas-control / recirculating fumigation systems.

Answer:

Materials: higher-grade coatings (e.g., Al-Zn-Mg series), thicker galvanizing; for welded silos use zinc-rich primer + weather-resistant topcoat systems.

Details: minimize exposed joints; apply secondary coating to key areas (skirt, interfaces, weld seams).

Maintenance: annual inspections and touch-up painting; improve drainage and ventilation to reduce moisture.

Answer:

Fastest: spiral folded (Lipp) silo (continuous rolling; shell can be formed in days).

Also fast: corrugated bolted silo (standardized parts; parallel installation).

Slower: welded silo (many welding/NDT/coating steps).

Tip: parallel construction, early delivery planning, and staggered civil/steel works can significantly shorten total duration.

Answer:

Large grain capacity: corrugated bolted silo offers the lowest cost per ton.

Small-to-medium industrial projects: bolted silos are reasonably priced and reusable after relocation.

Small scale but high airtightness / fast build needed: Lipp silo is an option—note equipment amortization costs.

Principle: compare life-cycle cost (LCC), not only initial cost.

Answer:

Grain: aeration, temperature monitoring, airtight fumigation, grain surface pressure equalization, anti-condensation.

Industrial powders: fluidized bottom / multi-point discharge / air slides, anti-arching, dust control & negative-pressure collection, safety valves and overpressure relief.

Common: level measurement, structural strength checks, cost control.

Answer:

Corrugated bolted: first choice for grain; low cost, fast build, mature supporting systems.

Spiral folded: fastest build and good airtightness; suitable for airtight and fast-track projects.

Bolted: small-to-medium industrial storage; easy to dismantle and relocate.

Welded: extra-large capacity / long-term airtight storage; long life but highest CAPEX and longest schedule.

Answer (typical experience ranges):

Grain: recommended ≤ ~2,500 t

Industrial granular: recommended ≤ ~2,000 t

With special reinforced design: ~3,000–5,000 t is possible, but structural and cost pressures increase significantly.

Answer:

Define peak inventory / safety stock / daily throughput → set single-silo capacity and redundancy (≥1 silo as maintenance backup).

Common for grain: large flat-bottom main storage + small hopper-bottom turnover silos; for industrial bulk: flat-bottom main silo + hopper buffer silos for loading.

Balance the line based on site, upstream supply rhythm, and downstream dispatch rhythm.

Answer:

Structure: flat-bottom multi-point discharge, large hopper angle (for hopper-bottom), low-friction liners.

Auxiliary: aeration pads/pipes, air slides, anti-arching devices.

Process: control moisture content and fineness distribution; keep stable in/out rhythm.

Answer:

Aeration system (bottom ducts + roof exhaust) and temperature cables;

Airtight fumigation / circulation facilities; grain cooling when necessary;

Grain surface leveling, anti-condensation, rodent/insect prevention; establish monitoring and early-warning mechanisms.

Answer:

Check EPC end-to-end capability: process, detailed design, manufacturing, civil/installation coordination, commissioning.

Review similar references and operating years under similar climate/material conditions.

Audit manufacturing equipment and quality system (welding/coating/testing qualifications); confirm after-sales response and spare parts support.

Answer:

Cold regions: insulation, thermal bridge treatment, ventilation for anti-condensation, low-temperature toughness materials.

Hot/desert: light-colored coatings for temperature reduction, enhanced roof ventilation.

High humidity/coastal: higher-grade coatings, anti-water-accumulation detailing, dehumidification.

Dusty/sandy: add sand filters, improve sealing, increase maintenance frequency.

Answer: prioritize food-contact-friendly materials (stainless steel / food-grade liners), easy-to-clean internal surfaces, non-toxic and corrosion-resistant; avoid hygienic dead corners; provide inspection and dry/wet cleaning access paths.

Answer: fumigation relies on pesticides reaching lethal concentration in an airtight space; controlled atmosphere suppresses insects/mold by reducing oxygen or increasing CO₂. Both require high airtightness.

Answer: Not necessarily. Whether insulation is needed depends on climate, storage duration, material moisture, and on-site management capability. Insulation is one method to control the “temperature difference → condensation → deterioration” chain, not a universal requirement.

Contact US Now!